A flexible screw conveyor is a mechanical conveyance system that moves solid bulk commodities like powder, pellets, and granulates across a facility. The mode of transit may be horizontal, inclined, or a combination of the two with some curves. Read More…

We are a US based, family owned company specializing in the design and manufacturing of screw conveyors in all configurations: vertical, inclined, shaftless, live bottom, plug screws, feeders, mixers, heating/cooling, FDA/USDA approved, screw presses and more.

Automated Flexible Conveyor (AFC) designs and manufactures the SPIRALFEEDER(TM) flexible screw conveyors to automatically transfer, load, weigh, and unload powders, pellets, granules, mixtures, and other dry, bulk materials fast, gently, and safely. Expert engineers offer decades of experience in designing the ideal custom screw conveyor for your bulk material handling application. Try your...

ISC Manufacturing LLC has specialized in screw conveyor manufacturing since 1976. Experts in the field of CNC machining, ISC designs & manufactures custom feeders, mixing & drag conveyors, bucket elevators, ribbon & paddle mixers, chutes & more. Our screw conveyor technology is such that our conveyors are capable of conveying, feeding, elevating & mixing. Ask about our service repair center!

At Akona Process Solutions, we take pride in engineering screw conveyors that provide reliable and efficient material handling for a wide range of industries. We design our conveyors to move bulk materials with precision, ensuring smooth and consistent flow whether the application involves powders, granules, or heavier solids.

At ProcessBarron, we specialize in delivering engineered material handling solutions that keep industrial operations moving efficiently and reliably. Our expertise in screw conveyors allows us to design and manufacture equipment that handles a wide range of bulk materials with precision and durability.

At Screw Conveyor Parts, LLC, we take pride in being a trusted resource for everything related to screw conveyors. We offer a comprehensive selection of screw conveyor components and systems designed to meet the demands of a wide range of industries, including agriculture, food processing, wastewater treatment, and manufacturing.

More Flexible Screw Conveyor Manufacturers

Flexible Screw Conveyors: Design, Applications, Benefits & Buying Guide

Flexible screw conveyors, also referred to as flexible auger conveyors or helical screw conveyors, are specialized equipment used for the efficient movement of bulk materials in a wide range of industrial and manufacturing environments. These versatile conveyors are particularly suitable for conveying powders, granules, pellets, flakes, and a variety of dry bulk solids in food processing, pharmaceuticals, plastics, chemicals, agriculture, and many other industries. Their unique design enables efficient and continuous transfer of materials along a flexible, routed path, helping plants optimize space utilization and streamline material handling processes.

Wondering if a flexible screw conveyor is right for your process? Looking for a reliable way to automate powder or granule transfer with minimal maintenance? Explore our comprehensive guide below covering design features, benefits, common applications, key decision factors, and expert tips for sourcing the best flexible screw conveyor manufacturers.

What is a Flexible Screw Conveyor?

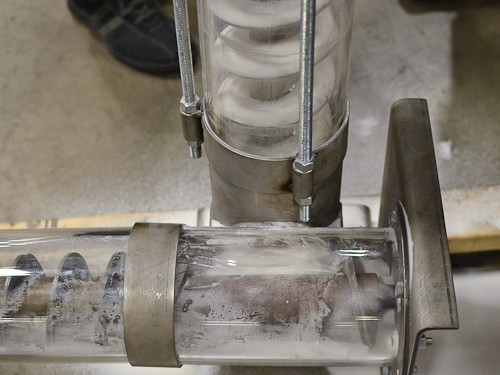

A flexible screw conveyor is a mechanical bulk material handling solution that utilizes a rotating helical screw (also known as an auger) inside a flexible plastic or polymer tube to move materials over short to moderate distances. Unlike rigid screw conveyors, flexible models can be routed around obstacles, between floors, or through tight spaces, making them ideal for customized plant layouts and retrofitting existing equipment lines.

Typical flexible screw conveyors are limited to conveying distances of 5-10 meters (approximately 16-33 feet), although with optimal design, conveying up to 20 meters (around 66 feet) may be possible. Their modular construction consists of several core components:

- Flexible Tube: Typically made of durable polymers such as polyamide or special polyethylene, allowing routing flexibility.

- Screw Flight (Auger): A shaftless, flexible helical screw, usually constructed from stainless or mild steel, engineered to bend and move within the tube.

- Bearings & Seals: Ensure smooth rotation and prevent material leakage, maintaining product integrity and process cleanliness.

- Inlet and Outlet Assemblies: Facilitate controlled material entry and discharge for seamless integration with upstream and downstream equipment.

- Drive Unit: Usually positioned at the conveyor outlet, isolating the drive from direct product contact and reducing maintenance needs.

Key Parts of a Flexible Screw Conveyor System

- Maximum sensor level

- Manifold discharge

- Hopper minimum level sensor

- Bridge break unit

- Hopper frame

- Safety guard

- Hopper

- Electromechanical vibrator

- Electric anti-vibration dowels

- Flexible conveyor tube

- Outlet unit

How Does a Flexible Screw Conveyor Work?

The core principle is simple yet effective. The flexible screw (auger) rotates within a stationary, flexible tube. As it turns, the helical shape "scoops" material from the inlet, propelling it forward by both directional and centrifugal forces. This action gently moves powders, granules, and small particles along the desired conveying path, even through bends or vertical inclines up to 60 degrees. The lack of a central shaft minimizes product buildup and blockages, making flexible screw conveyors a robust solution for challenging flow characteristics.

Did you know? Flexible screw conveyors can be designed for horizontal material transport up to 80 feet (24 meters) or for inclined conveying (up to 60°) depending on application requirements. Common tube diameters range from 2.5 to 8 inches, providing a wide spectrum of throughput options for different bulk material transfer needs.

Flexible Screw Conveyor Design Considerations

When sizing and designing a flexible screw conveyor system, it's critical to evaluate several key factors affecting performance and efficiency:

- Spiral Rotational Velocity & Model Coefficient: Determines the rate at which material is conveyed. Higher RPM generally increases throughput, but must be balanced with product characteristics to prevent degradation.

- Conveyor Angle & Orientation: Horizontal, vertical, or inclined layouts affect system capacity and the type of screw required.

- Material Properties: Particle size, bulk density, abrasiveness, fluidity, and moisture content all influence proper conveyor selection.

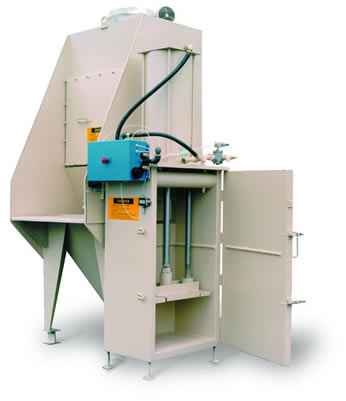

- Feed and Discharge Methods: Infeed hoppers, vibratory feeders, and manifold discharges can be customized for seamless process integration.

- Construction Materials: Food-grade stainless steel, carbon steel, and anti-static polymers are available to meet sanitary, chemical, or abrasive handling needs.

- Cleanability & Maintenance: Tool-less disassembly, CIP (Clean-In-Place) options, and easy tube access are essential for industries with frequent changeovers or strict hygiene requirements.

For example, a flexible screw conveyor with a 45-degree incline, 8-inch tube diameter, and 360 RPM speed can move up to 1800 cubic feet of material per hour. Conveyor screws are available in a variety of shapes—including square bar, round wire, flat wire, and beveled edge—to optimize flow, minimize product damage, and handle various materials.

Flexible Screw Conveyor Auger Types

Selecting the right auger design is vital for maximizing performance and product quality. Each auger type is engineered to address specific material challenges and optimize throughput.

Flat Wire Augers

Flat wire augers, constructed from rectangular or square wire, are ideal for conveying light powders and fragile materials. The flat conveying surface applies a higher positive forward force while reducing outward pressure against the tube wall. This design is especially beneficial for minimizing dust and maintaining product consistency in food, pharmaceutical, and chemical manufacturing.

Beveled or Square Bar Augers

Beveled or square bar augers are engineered for handling delicate or difficult-to-move materials. Their unique profile enables efficient transport with minimal product degradation or breakage. These augers operate at lower maximum RPMs (typically up to 600) to ensure gentle handling—ideal for seeds, grains, or friable powders.

Round Wire Augers

Best suited for heavy, dense, or highly abrasive materials, round wire augers are manufactured from coiled round bar. This auger design offers exceptional strength and flexibility, effectively reducing load stress caused by particle size, material weight, or irregular shapes. While round wire augers produce higher outward force and slippage, they are highly durable and provide reliable performance when conveying minerals, plastics, or aggressive chemicals.

Center Core Augers

Center core augers include a small tube running the length of the screw, limiting the amount of material entering the conveyor and managing pressure on the auger. This design is ideal for moving highly fluidized, aerated, or dense materials, as it prevents overloading and ensures steady, controlled flow.

Not sure which auger design is best for your material? Research auger conveyor types or consult with a flexible screw conveyor manufacturer for expert guidance.

Applications of Flexible Screw Conveyors

Flexible screw conveyors are renowned for their adaptability and reliability across a wide range of industries and bulk material handling scenarios. Common applications include:

- Food Processing: Transfer of flour, sugar, spices, grains, coffee, cocoa, salt, dried milk, or baking mixes.

- Pharmaceuticals: Conveying active ingredients, excipients, powders, and granules while maintaining strict hygiene.

- Plastics: Pellet, resin, regrind, and powder conveying in injection molding or extrusion lines.

- Chemicals: Handling detergents, pigments, catalysts, powders, and additives with options for corrosion resistance.

- Agriculture: Efficient transfer of feed, seed, grain, and fertilizer in farm automation systems.

- Minerals & Building Materials: Moving cement, sand, limestone, or ceramic powders in construction and mining operations.

- Waste & Recycling: Bulk solids handling for biomass, RDF, or scrap processing.

Want to see flexible screw conveyors in action? Search for video demonstrations or case studies from conveyor manufacturers to better understand how these systems can boost your operations.

Advantages of Flexible Screw Conveyors

Flexible screw conveyors offer a host of operational and economic benefits over alternative bulk material handling equipment such as pneumatic conveyors, belt conveyors, or rigid screw conveyors. Key advantages include:

- Flexible routing options—navigate around process obstacles, through walls, or between floors without complex redesign.

- Dust-tight and sanitary construction—ideal for sensitive or hazardous products.

- Minimal product degradation—gentle conveying action preserves particle shape and integrity.

- Versatility—conveys both free-flowing and non-free-flowing materials.

- Low capital and operating cost—cost-effective compared to pneumatic or vacuum conveyors.

- Simple maintenance—few moving parts, easy access for cleaning and inspection.

- Quick installation—lightweight, modular design for rapid plant integration or process upgrades.

- Energy efficient—lower power consumption compared to air-driven systems.

- Expandable—can be retrofitted or extended as plant needs evolve.

Limitations of Flexible Screw Conveyors

- Limited conveying distance and capacity—typically up to 20 meters and moderate bulk throughput.

- Residual product may remain in the tube after operation—may require cleaning for product changeover.

- Different screw types required for handling multiple product types—may not be suitable for frequent batch changes without auger swaps.

- Not ideal for extremely sticky, cohesive, or wet materials—may cause buildup or clogging in the tube.

- Maximum incline angle and tube length are restricted compared to some pneumatic systems.

Exploring alternatives? Learn how flexible screw conveyors compare to pneumatic conveying systems or belt conveyors for your specific application.

How to Choose the Best Flexible Screw Conveyor for Your Application

Selecting the right flexible screw conveyor involves evaluating your material characteristics, process layout, required throughput, and environmental or regulatory requirements. Here are crucial decision factors to consider:

- Material Compatibility: Is your product abrasive, fragile, sticky, or hygroscopic? Choose auger and tube materials accordingly (e.g., stainless steel for food, abrasion-resistant alloys for minerals).

- Sanitary or Hygienic Requirements: Does your process demand food-grade or pharmaceutical-grade construction? Look for conveyors with FDA-compliant materials and easy-clean features.

- Space Constraints: Does your facility require routing around existing equipment or through tight spaces? Flexible screw conveyors excel here.

- Process Integration: Will the conveyor feed directly from a silo, bulk bag unloader, or upstream processing equipment?

- Capacity & Throughput: What is your required transfer rate? Ensure correct tube diameter, auger type, and drive power.

- Maintenance & Downtime: How often will the system need to be cleaned or serviced? Modular, tool-free designs minimize downtime.

- Budget & ROI: Consider both initial investment and long-term operating costs when comparing conveyor solutions.

Need help specifying a conveyor? Ask suppliers for material testing, sample runs, or references from similar projects to validate performance.

Flexible Screw Conveyor Maintenance & Best Practices

Longevity and reliability of your flexible screw conveyor depend on proper installation, routine inspection, and timely maintenance. Follow these best practices to maximize uptime:

- Regularly inspect screw flights and tubes for wear, especially when conveying abrasive materials.

- Lubricate bearings and seals according to manufacturer recommendations.

- Check drive unit alignment and motor operation for smooth, vibration-free performance.

- Clean tubes and augers between product changeovers to prevent cross-contamination.

- Monitor sensors, vibratory aids, and level controls for optimal automation and product flow.

Looking for troubleshooting advice? Review manufacturer documentation or contact technical support for help with blockage, noise, or throughput issues.

Choosing the Right Flexible Screw Conveyor Manufacturer

To ensure the best return on your investment, it’s important to work with reputable and experienced flexible screw conveyor manufacturers who can provide custom engineering, robust after-sales support, and application expertise. Here’s how to get started:

- Compare at least 4-5 conveyor manufacturers using a flexible screw conveyor directory to assess capabilities and specialization.

- Review each supplier’s business profile, project portfolio, and customer testimonials to gauge industry experience.

- Use proprietary website previewers to quickly evaluate product ranges and technical resources.

- Request and compare detailed RFQs (Request for Quote) for your specific application—include process drawings, material data, and performance criteria.

- Ask about available material testing, pilot plant demonstrations, and after-sales service.

- Consider suppliers offering rapid spare parts, on-site training, and technical support for long-term reliability.

Ready to take the next step? Use our simple RFQ form to contact multiple flexible screw conveyor companies and request a quote tailored to your project requirements.

Frequently Asked Questions (FAQs) About Flexible Screw Conveyors

What materials can flexible screw conveyors handle?

Flexible screw conveyors are suitable for most free-flowing and semi-free-flowing bulk solids including powders, granules, pellets, flakes, and dry mixtures. They are not recommended for sticky, cohesive, or wet materials.

How do I clean a flexible screw conveyor?

Most designs allow for quick disassembly without tools. Remove the tube and screw, then clean with compressed air, brushes, or CIP (Clean-In-Place) systems as needed. Always follow manufacturer maintenance guidelines.

What is the maximum conveying angle?

Flexible screw conveyors can be installed at angles up to 60 degrees. However, capacity decreases as the incline increases—consult your manufacturer for application-specific recommendations.

Can flexible screw conveyors be used for hazardous or sanitary applications?

Yes, suppliers offer USDA, FDA, and ATEX-compliant options for hygienic, food-safe, or explosion-risk environments. Specify your requirements when requesting a quote.

Conclusion: Is a Flexible Screw Conveyor Right for Your Operation?

Flexible screw conveyors are a highly versatile, cost-effective, and efficient solution for bulk material transfer in a wide range of industries and applications. Their unique combination of routing flexibility, gentle conveying action, and low maintenance make them an excellent choice for many production lines and processing plants. By carefully evaluating your material properties, throughput requirements, and process layout, you can select a flexible screw conveyor system that delivers long-term performance and value.

Still have questions? Contact us or browse our knowledge base to learn more about flexible screw conveyor solutions, technical specifications, and supplier recommendations.

Bulk Bag Handling

Bulk Bag Handling Industrial Dryers

Industrial Dryers Mixers & Blenders

Mixers & Blenders Palletizers

Palletizers Pneumatic Conveyors

Pneumatic Conveyors Screw Conveyors

Screw Conveyors Vibratory Feeders

Vibratory Feeders Weighing Systems & Scales

Weighing Systems & Scales Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services