More Screw Conveyor Manufacturers

Applications

Screw conveyors, also known as auger conveyors or helical screw conveyors, are engineered to efficiently transport a wide array of bulk materials—including powders, granules, pellets, flakes, and even semi-solid substances—from one location to another within manufacturing or processing facilities. This reliable bulk material handling equipment is indispensable for moving items such as packages, equipment, food products, and industrial materials in a safe, controlled manner. They play a pivotal role in supporting automated and semi-automated finishing and manufacturing processes, optimizing workflow, and reducing manual labor requirements.

Industries that rely on screw conveyors include construction, oil and gas, mining, chemical processing, pharmaceuticals, plastics, food and beverage processing, agriculture, wastewater treatment, recycling, and biomass energy production. These industries require efficient, hygienic, and reliable means of moving materials between pits, trucks, barrels, rail cars, silos, hoppers, vats, and other storage or processing units.

In the agriculture sector, screw conveyors are essential for transferring grains, seeds, and animal feed between storage bins, silos, and processing machinery such as balers, threshers, and grain elevators. Efficient material transfer helps prevent product loss and contamination, supporting high crop yields and efficient livestock feeding operations.

Within food processing plants, auger conveyors ensure the hygienic transport of dry ingredients—such as sugar, flour, salt, coffee, cocoa, nuts, spices, and cereal grains—between processing steps, packaging lines, and storage silos. Food-grade stainless steel screw conveyors are crucial for maintaining food safety standards and preventing cross-contamination.

In construction and building materials manufacturing, industrial screw conveyors are used to blend, mix, and transport wet and dry components like cement, plaster, sand, lime, fly ash, and aggregates. This supports efficient concrete production, block making, and mortar mixing operations.

Additional industries benefiting from screw conveyor systems include:

- Mining: For handling coal, ore, tailings, and other minerals.

- Chemical and Plastics: For conveying resins, pigments, powders, and additives in controlled environments.

- Pharmaceuticals: For transporting active pharmaceutical ingredients (APIs), excipients, and finished products under strict sanitary conditions.

- Wastewater treatment: Removing sludge, grit, and biosolids in municipal and industrial treatment plants.

- Recycling: Moving shredded plastic, paper, glass, and metal particles in sorting and processing facilities.

Are you looking for a screw conveyor solution tailored to your specific industry or application? Discover specialized manufacturers and request a quote for your unique materials handling requirements.

History

The history of screw conveyors can be traced back to the 3rd century BC, when the renowned Greek scientist and mathematician Archimedes invented the Archimedes’ screw, also known as the screw pump. This ingenious invention was inspired by earlier auger conveying systems observed during Archimedes’ travels in Egypt and the Ancient Near East, where similar mechanisms were utilized for irrigation and water management. Assyrian cuneiform tablets record the fabrication of bronze water screws during the reign of King Sennacherib (704-681 BC), and the classical Greek historian Strabo referenced the use of augers in the fabled Hanging Gardens of Babylon.

Archimedes’ revolutionary design consisted of a hollow cylinder containing a central shaft encircled by a helical spiral or auger. As this assembly rotated, it efficiently lifted water or other materials, enabling irrigation of crops, draining of wetlands, and bilge pumping for ships. The principle of the Archimedean screw laid the groundwork for subsequent developments in mechanical conveying systems.

By the early 15th century, German engineer Konrad Kyeser documented the use of a crank-enhanced Archimedes’ screw in his treatise Bellifortis, which quickly replaced earlier models. The industrial era saw the evolution of the modern screw conveyor system, particularly in the United States between the late 19th and mid-20th centuries. During this time, screw conveyors—often called grain augers—became vital in agricultural processing, especially for grain and feed handling. Their role expanded to support the burgeoning commercial food industry, handling perishable food ingredients and supporting automation in feed mills and factories.

The 20th century witnessed significant material and design innovations, such as the introduction of stainless steel screw conveyors for enhanced durability, corrosion resistance, and sanitation—vital for food, chemical, and pharmaceutical applications. Automation, robotics integration, and the development of custom screw conveyor systems have since revolutionized bulk material handling, increasing efficiency, reducing labor costs, and improving safety across countless industries.

Curious about the evolution of screw conveyor technology and its impact on modern manufacturing? Explore our industrial screw conveyor resources for a deeper historical perspective.

How Screw Conveyors Work

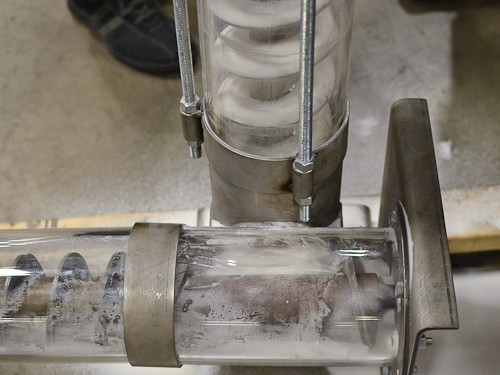

Screw conveyors operate based on the Archimedes’ screw principle—a helical screw or auger, rotating inside a trough or tubular casing, pushes materials along the conveyor’s axis. As the screw turns, it moves bulk materials forward through the enclosed or open channel, creating a consistent, controlled flow. This makes screw conveyors ideal for both horizontal and inclined material transfer, as well as vertical conveying in certain configurations.

Material flow rates are carefully controlled and can be measured in cubic feet per hour, pounds per hour, or tons per hour, depending on the specific requirements. The screw’s pitch, diameter, rotational speed, and inclination angle all affect the system’s throughput and efficiency. Power is typically supplied by electric motors, but some applications leverage gravity or power from auxiliary equipment.

Screw conveyors can be customized with different flight types—such as ribbon, paddle, or cut-and-fold flights—to optimize handling of sticky, fibrous, abrasive, or free-flowing materials. They are also available as shafted or shaftless designs, open or enclosed systems, and with various discharge and feeding options.

Want to learn how to select the right screw conveyor type for your process? Read our guide on screw conveyor system selection.

Types of Screw Conveyors and Related Conveyor Systems

There are many types of screw conveyors and related conveyor systems, each designed for particular materials, layouts, and operational requirements. Understanding these options is crucial for selecting the right bulk material handling solution for your application.

- Belt Conveyors: The most prevalent conveyor type, utilizing a continuous rubber or polymer belt looped around pulleys to transport bulk or packaged materials. Popular in distribution centers, airports, and assembly lines.

- Chain Conveyors: Employ a chain drive mechanism to move abrasive, fragile, or dry materials. The adjustable gear ratio provides speed control and energy efficiency.

- Roller Conveyors: Feature cylindrical rollers that can be gravity-driven or powered, ideal for moving heavier loads, packages, and palletized materials in warehouses and shipping facilities.

- Spiral Conveyors: Incorporate a helical screw enclosed within a tube, suitable for gentle vertical or inclined transport of bulk materials, especially where space is limited.

- Overhead Conveyors: Mounted above working areas, these conveyors free up valuable floor space and are used for assembly, sorting, and finishing lines. They can be gravity-fed or powered by motors, pneumatics, or vacuum.

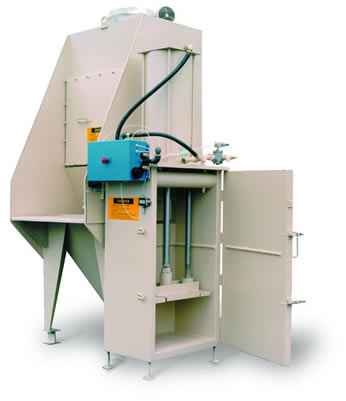

- Vertical Screw Conveyors: Also called vertical auger conveyors, designed to lift materials between floors or processes. They use tubular casings and offer a compact, space-saving alternative to bucket elevators.

- Horizontal Screw Conveyors: Move materials in a linear, horizontal path along a trough, suitable for mixing, compaction, aeration, heating, cooling, drying, or dewatering tasks.

- Inclined Screw Conveyors: Transport bulk materials upward or downward at an angle, requiring more power but enabling multi-floor transfer or feeding elevated equipment.

- Gravity Conveyors: Use gravity, rather than motors, to move items down a sloped path. Examples include ball transfer and chute conveyors—ideal for low-cost material movement.

- Tubular Drag Conveyors: Feature chain-driven flights inside a sealed tube, efficiently moving bulk materials at high speeds and over long distances with minimal dust emissions.

- Pneumatic Conveyors: Use air pressure or vacuum to move fine powders and granules through closed tubes, minimizing contamination and material loss. Popular for handling sensitive materials in food, chemical, and pharmaceutical industries.

- Flexible Screw Conveyors: Feature a flexible, rotating spiral within a flexible or semi-rigid tube, capable of bending and adapting to complex plant layouts and multiple feed or discharge points.

- Portable Screw Conveyors: Mounted on casters, carts, or vehicles for easy relocation. Commonly used to move powdered, granulated, or pelletized materials between processing stations or storage containers.

- Vibratory Conveyors: Use oscillating troughs or trays powered by electromagnetic or electromechanical vibrators to move bulk materials such as gypsum, fertilizer, crushed cement, minerals, glass, or food products.

- Bucket Elevators: Employ a series of buckets attached to a belt or chain to vertically lift flowable materials. Often used in conjunction with screw conveyors for multi-stage material handling.

Not sure which conveyor system best fits your application? Ask our experts: What is the best conveyor system for handling your specific material or process requirements?

Equipment Components and Construction

A typical screw conveyor assembly includes several key components:

- Conveyor Screw (Helicoid Flighting): The rotating helical blade, or auger, that physically moves materials along the conveyor’s axis.

- Trough or Tubular Casing: The housing that encases the screw, available in U-shaped, tubular, or custom profiles to suit material flow and sanitation needs.

- Drive Unit: Comprising an electric motor, gear reducer, shaft coupling, and shaft seal. Some systems use chain drives or direct-coupled motors.

- End Bearings and Hangers: Support the screw shaft and maintain alignment, especially in long conveyors.

- Infeed and Discharge Openings: Customizable to integrate with upstream and downstream equipment, hoppers, or chutes.

- Cover or Access Panels: For safety, dust control, and easy inspection or cleaning.

Shaftless screw conveyors, which omit the central shaft, are designed for handling sticky, stringy, or difficult-to-convey materials. They offer reduced clogging risk and easier maintenance. Modular designs, quick-release couplings, and easy-clean features are available for sanitary or high-throughput applications.

Interested in learning more about conveyor construction and customization? Explore our industrial screw conveyor design options.

Benefits of Screw Conveyors

Screw conveyors deliver a robust set of advantages for bulk material handling, making them a popular choice across numerous industries:

- Gentle Handling and Mixing: The rotating auger gently conveys materials, minimizing degradation, dust production, and product loss—essential for food, pharmaceutical, and fragile materials.

- Efficiency and Throughput: Screw conveyors offer consistent, controlled material flow, boosting process efficiency and supporting automated operations.

- Cost-Effectiveness: Compared to other conveyor types, screw conveyors are affordable to purchase, install, and maintain—ideal for both small businesses and large industrial plants.

- Versatility and Customization: Suitable for an extensive range of materials—including abrasive, corrosive, sticky, or fine powders—due to customizable designs, materials, and configurations.

- Space Optimization: Screw conveyors can be designed for horizontal, inclined, or vertical installation, adapting to various plant layouts and spatial constraints.

- Sanitary Operation: Stainless steel or food-grade constructions enable hygienic, easy-to-clean systems for food and pharmaceutical processing.

- Durability and Longevity: Robust construction, wear-resistant materials, and modular designs ensure long service life and minimal downtime.

- Safe and Enclosed Conveying: Enclosed screw conveyors prevent spillage, contamination, and exposure to hazardous materials, supporting workplace safety and regulatory compliance.

Need help evaluating the ROI of a screw conveyor vs. other bulk material handling systems? Contact our team for a cost-benefit analysis tailored to your production needs.

Design and Customization

Materials of Construction

Most screw conveyors are fabricated from metals—such as carbon steel, stainless steel, or specialty alloys—chosen for their strength, corrosion resistance, and hygienic properties. Stainless steel, especially food-grade 304 or 316 SS, is the preferred choice for industrial, food, pharmaceutical, and chemical processing applications due to its smooth, non-contaminating surface and ease of cleaning.

For applications requiring high impact resistance, material purity, or reduced weight—such as plastics manufacturing or food processing—engineers may specify injection-molded thermoplastic resin construction. Specialty coatings, hardened flight surfaces, or abrasion-resistant liners further enhance conveyor durability in harsh environments.

Key Design Considerations

When designing or specifying a screw conveyor, manufacturers and engineers must evaluate several critical factors:

- Material Properties: Consistency, bulk density, flowability, abrasiveness, size, moisture content, temperature, corrosiveness, and flammability.

- Application Requirements: Volume and frequency of material transfer, required throughput, distance and elevation changes, temperature or sanitary constraints, and integration with other equipment.

- Conveyor Orientation: Horizontal, inclined, or vertical layouts, each with unique power and design implications.

- Power Source: Electric motors are common, but some conveyors utilize hydraulic, pneumatic, or even manual power in specialized settings.

- Accessories and Custom Features: Options such as wash-down sections, mobile base units for portability, flexible discharge hoses, bag dump hoppers, access and inspection ports, and dust-tight or explosion-proof enclosures.

For example, food processors may require quick-disconnect covers, sanitary welds, and easy access for cleaning, while chemical plants may specify explosion-proof motors and corrosion-resistant linings.

Looking for a custom screw conveyor design? Request a quote from leading manufacturers to compare options and features.

Safety and Compliance Standards

Safety and compliance are paramount in any bulk material handling system. In the United States, selecting a CEMA-certified screw conveyor ensures adherence to strict engineering and safety standards set by the Conveyor Equipment Manufacturers Association. CEMA certification covers critical aspects including conveyor design, construction, performance, and safe operating procedures.

Additional industry-specific standards and certifications may apply:

- FDA (Food and Drug Administration): For food processing conveyors, ensuring sanitary design, non-toxic materials, and easy cleaning.

- USDA (United States Department of Agriculture): For grain, feed, and agricultural conveyors, ensuring food safety and hygiene.

- OSHA (Occupational Safety and Health Administration): For compliance with workplace safety regulations, guarding, and emergency stop systems.

- ATEX/IECEx: For conveyors used in hazardous, explosive environments (e.g., chemical processing or dust-handling applications).

- 3-A Sanitary Standards: For dairy and beverage applications.

Be sure to consult with industry experts and regulatory authorities to ensure your screw conveyor system meets all necessary safety and compliance requirements before purchase and installation.

Have questions about conveyor compliance or industry certifications? Contact our compliance specialists for guidance tailored to your sector.

How to Find the Right Screw Conveyor Manufacturer

Choosing the right screw conveyor manufacturer is critical for ensuring your project’s success, long-term reliability, and regulatory compliance. Here’s what to consider when evaluating suppliers:

- Experience and Reputation: Look for manufacturers with a proven track record in your industry and positive customer reviews.

- Customization Capability: Can the manufacturer design and build a conveyor system tailored to your exact specifications, standards, and application needs?

- Quality Assurance: Does the supplier use high-quality materials, skilled fabrication methods, and rigorous testing protocols?

- Regulatory Compliance: Are their designs certified to meet CEMA, FDA, USDA, OSHA, or other relevant standards?

- Customer Support: Will the manufacturer provide pre-sale engineering support, CAD drawings, installation guidance, and after-sales service?

- Value and Total Cost of Ownership: Consider not only the initial purchase price but also long-term maintenance, energy efficiency, and potential downtime costs.

Remember, the best screw conveyor manufacturer is not always the cheapest, but the one who can provide a solution that meets your unique requirements—without compromising on quality, lead time, or support. A reputable supplier will partner with you throughout the project, offering clear communication, technical expertise, and responsive service.

Ready to get started? Browse our comprehensive listings of screw conveyor manufacturers or request a custom quote to find the perfect match for your project. Our resource hub also offers in-depth guides, technical articles, and case studies to help you make an informed decision.

Still have questions? Contact our team for personalized assistance or check out our FAQ section for answers to common screw conveyor questions, including selection, installation, and maintenance best practices.

What are the primary applications of screw conveyors?

Screw conveyors are used to transport bulk materials such as powders, granules, pellets, flakes, and semi-solids efficiently within manufacturing and processing facilities. Industries using screw conveyors include agriculture (for grains and animal feed), food and beverage (for dry ingredients), construction (for cement and aggregates), mining, pharmaceuticals, chemical processing, plastics, wastewater treatment, recycling, and biomass energy production.

How do screw conveyors work?

Screw conveyors operate using a rotating helical screw or auger inside a trough or tube. As the screw turns, it pushes materials along the conveyor’s axis, allowing controlled bulk material flow for horizontal, inclined, or vertical conveying. Key variables include screw pitch, diameter, speed, and inclination angle, with power usually supplied by electric motors.

What are the main types of screw conveyors and related systems?

Types of screw conveyors include horizontal, inclined, and vertical screw conveyors, as well as flexible and portable screw conveyors. Related systems include belt conveyors, chain conveyors, roller conveyors, spiral conveyors, overhead conveyors, gravity conveyors, tubular drag conveyors, pneumatic conveyors, vibratory conveyors, and bucket elevators. Each is designed for specific materials, layouts, or processing requirements.

What are the key components of a screw conveyor?

A typical screw conveyor includes a conveyor screw (helical flighting), trough or tubular casing, drive unit (motor, gear reducer, shaft coupling), end bearings and hangers, infeed and discharge openings, and cover or access panels. Shaftless designs are also available for handling sticky or stringy materials and offer easier maintenance.

What are the main benefits of using screw conveyors?

Screw conveyors offer gentle handling, efficiency, cost-effectiveness, and space optimization. They are highly customizable, suitable for a wide range of materials, and can be built for sanitary operation with easy cleaning. They also provide durability, safe enclosed conveying, and support automated or semi-automated processes in various industries.

What design considerations are important for screw conveyors?

Key considerations include material properties (such as density, abrasiveness, and flowability), application requirements (throughput, distance, elevation), layout orientation, power source, and the need for custom features like wash-down sections or explosion-proof construction. Materials of construction, such as carbon steel, stainless steel, or thermoplastics, are chosen based on application needs.

What safety and compliance standards apply to screw conveyors?

Screw conveyors should comply with CEMA standards for design, construction, and safety. Additional standards may include FDA and USDA requirements for food processing, OSHA regulations for workplace safety, ATEX/IECEx for explosive environments, and 3-A Sanitary Standards for dairy applications. Consulting with regulatory experts helps ensure compliance.

How do I choose the right screw conveyor manufacturer?

Select a manufacturer with industry experience, proven customization capabilities, strong quality assurance, compliance with relevant standards (such as CEMA, FDA, OSHA), and excellent customer support. Evaluate not just price, but also service, maintenance, and the supplier’s ability to meet your project’s unique requirements.

Bulk Bag Handling

Bulk Bag Handling Industrial Dryers

Industrial Dryers Mixers & Blenders

Mixers & Blenders Palletizers

Palletizers Pneumatic Conveyors

Pneumatic Conveyors Screw Conveyors

Screw Conveyors Vibratory Feeders

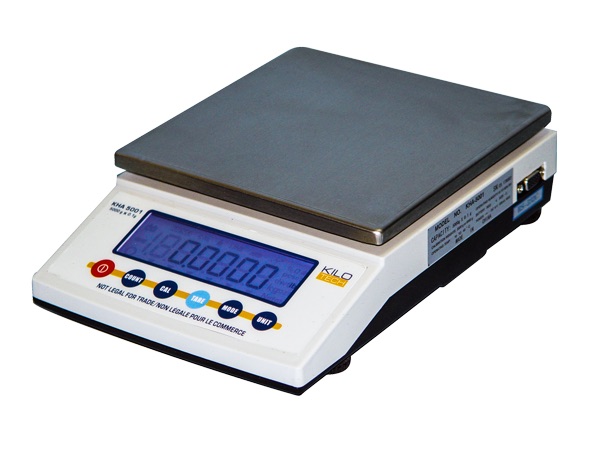

Vibratory Feeders Weighing Systems & Scales

Weighing Systems & Scales Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services