Bucket elevators are machines designed to move materials vertically from one level to another. They are commonly used in industrial and commercial settings to transport bulk materials such as grains, coal, minerals, and chemicals materials that need to be transported vertically but are too heavy, too abrasive, or too fragile for other types of conveyors. This article will provide an overview of bucket elevators, including their components, types, benefits, and applications. Read More...

PPM Technologies Holdings, LLC is an innovative industry leader in the vibratory feeder industry. Our main focus has always been to provide our customers with high-quality products with the exact specifications for their needs. With our wide range of products, we are able to serve various industries.

Our company has manufacturing experiences dating back to 1977 and over the years we have expanded into a high-end supplier of innovative screw conveyors. Here at Conveyor Engineering & Manufacturing we have a mission to provide our customers with outstanding services and reliable products. Operating out of an 116,000 square foot facility in Cedar Rapids, Iowa we excel at manufacturing highly...

More Bucket Elevator Manufacturers

Components of Bucket Elevators

A bucket elevator is a type of vertical conveyor that uses buckets to carry materials from the bottom to the top of a structure. The buckets are attached to a belt or chain that rotates around a set of pulleys. As the belt or chain rotates, the buckets scoop up materials from the bottom and carry them to the top, where they are discharged. These, and other, common components of bucket elevators are discussed below in greater detail.

Buckets

The buckets are the containers that carry the materials. They are typically made of metal, plastic, or rubber and come in various shapes and sizes depending on the material being transported.

Belt or Chain

The belt or chain is what drives the buckets. It rotates around a set of pulleys, which moves the buckets up and down.

Pulleys

The pulleys are used to guide and support the belt or chain. They come in various sizes and shapes and are made of metal or plastic.

Drive Unit

The drive unit is what powers the belt or chain. It can be an electric motor, hydraulic motor, or pneumatic motor.

Head Section

The head section is where the buckets are mounted to the belt or chain. It also contains the discharge chute where the materials are unloaded.

Boot Section

The boot section is where the buckets are loaded with materials. It also contains the inlet chute where the materials are fed into the elevator.

Bucket Elevator Belt

The bucket elevator belt is a specialized type of conveyor belt designed for bucket elevators. It is made of rubber or PVC and has special reinforcements to withstand the weight of the materials being transported.

Types of Bucket Elevators

There are several types of bucket elevators, each designed for specific applications. The three main types of bucket elevators are:

Centrifugal Bucket Elevators

These are the most common types of bucket elevators. They use centrifugal force to discharge the materials from the buckets as they reach the top of the elevator. They are best suited for handling lightweight, non-sticky materials such as grains, sugar, and fertilizers.

Continuous Bucket Elevators

These elevators use a single chain or belt with evenly spaced buckets to transport materials. They are best suited for handling abrasive materials such as sand, gravel, and glass.

Positive Discharge Bucket Elevators

These elevators are similar to centrifugal bucket elevators but are designed to discharge materials using a series of small buckets that rotate around a vertical axis. They are best suited for handling sticky or wet materials such as wet grains or sludges.

Bucket elevators can also be designed with various features such as explosion-proofing, self-cleaning, and adjustable speed control to meet specific application requirements.

Considerations Regarding Bucket Elevators

While bucket elevators offer several benefits, they also have some considerations that should be taken into account. Firstly, safety is a major concern, and appropriate safety measures should be implemented to prevent accidents. Maintenance is also crucial to prevent breakdowns, and the cost of installation and customization can be significant.

Benefits of Bucket Elevators

Despite these considerations, bucket elevators offer several benefits that make them a valuable asset in many industries. These benefits include:

Increased Efficiency

Bucket elevators can transport materials vertically, which saves space and reduces the need for multiple conveyors. This can increase production efficiency and reduce labor costs.

Cost Savings

Bucket elevators can transport large quantities of materials with minimal labor costs. They also require less maintenance compared to other types of conveyors, which can result in long-term cost savings.

Space Savings

Bucket elevators require less floor space compared to other types of conveyors. This makes them ideal for installations in tight spaces or buildings with limited floor space.

Applications of Bucket Elevators

Bucket elevators are used in a wide range of industries to transport bulk materials vertically. Some of the most common applications of bucket elevators include:

Agriculture and Farming

Bucket elevators are used to transport grains, seeds, and other agricultural products from storage to processing facilities.

Construction

Bucket elevators are used to transport construction materials such as sand, gravel, and concrete from ground level to higher floors.

Mining and Minerals

Bucket elevators are used to transport minerals such as coal, iron ore, and copper ore from mining sites to processing plants.

Food and Beverage Processing

Bucket elevators are used to transport food products such as grains, flour, and sugar from storage to processing facilities.

Chemical and Petrochemical Industries

Bucket elevators are used to transport chemicals, plastics, and other raw materials from storage to processing facilities.

Cement Industry

Bucket elevators are used to transport cement, limestone, and other materials from storage to processing facilities.

Recycling and Waste Management

Bucket elevators are used to transport waste materials such as glass, plastic, and metal from recycling centers to processing facilities.

Choosing the Right Bucket Elevator Manufacturer

To ensure you have the most beneficial outcome when purchasing a bucket elevator from a bucket elevator manufacturer, it is important to compare several companies using our directory of bucket elevator manufacturers. Each bucket elevator manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or to request a quote. Review each bucket elevator business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple bucket elevator companies with the same form.

Bulk Bag Handling

Bulk Bag Handling Industrial Dryers

Industrial Dryers Mixers & Blenders

Mixers & Blenders Palletizers

Palletizers Pneumatic Conveyors

Pneumatic Conveyors Screw Conveyors

Screw Conveyors Vibratory Feeders

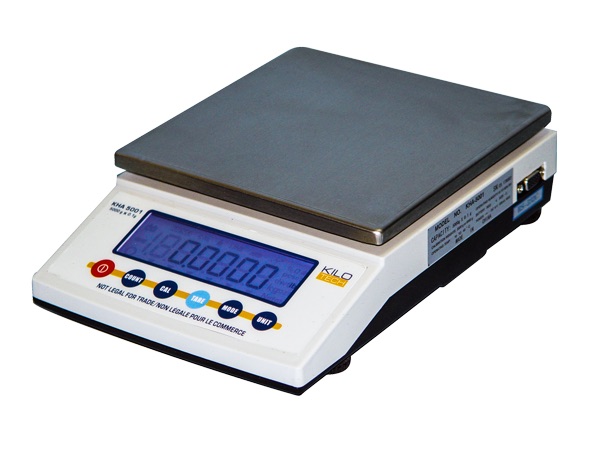

Vibratory Feeders Weighing Systems & Scales

Weighing Systems & Scales Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services