Inclined screw conveyors are used in a few different applications within the process industry. These applications include the agricultural, construction and food and beverage industries. They transport raw materials like cement, fertilizer, feed, sugar and meat. Read More…

We are a US based, family owned company specializing in the design and manufacturing of screw conveyors in all configurations: vertical, inclined, shaftless, live bottom, plug screws, feeders, mixers, heating/cooling, FDA/USDA approved, screw presses and more.

Automated Flexible Conveyor (AFC) designs and manufactures the SPIRALFEEDER(TM) flexible screw conveyors to automatically transfer, load, weigh, and unload powders, pellets, granules, mixtures, and other dry, bulk materials fast, gently, and safely. Expert engineers offer decades of experience in designing the ideal custom screw conveyor for your bulk material handling application. Try your...

At Akona Process Solutions, we take pride in engineering screw conveyors that provide reliable and efficient material handling for a wide range of industries. We design our conveyors to move bulk materials with precision, ensuring smooth and consistent flow whether the application involves powders, granules, or heavier solids.

Conveyance Solutions by Continental is a leading manufacturer of bulk material-handling equipment. We design equipment to suit your needs through manufacturing, prompt delivery and installation and start-up. We serve the cement, coal, food, gypsum and other industries. We construct with carbon steel, various grades of stainless steel and other exotic metals. Call today for screw conveyors.

At American Bin and Conveyor, we specialize in designing and manufacturing screw conveyors that keep material handling efficient, reliable, and tailored to the needs of our customers. We take pride in engineering conveyors that move bulk materials with precision, whether handling powders, grains, aggregates, or other challenging materials.

More Inclined Screw Conveyor Manufacturers

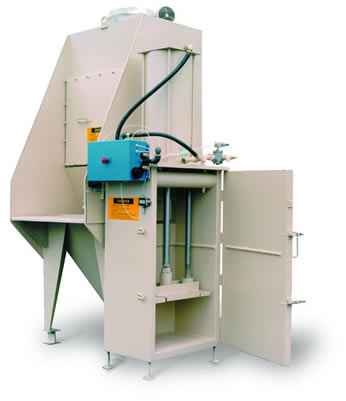

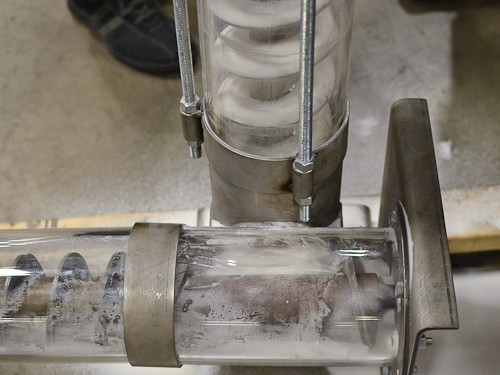

Commonly seen in the food industry, these conveyors transport ingredients to and from mixers, ovens and vats and need to be sterile at all times. Therefore, they are commonly made of stainless steel, a smooth food grade metal that is less likely to contaminate edible ingredients than other materials and is easily cleaned. Like all industrial screw conveyors, those that are inclined use a spiral, rotating screw within a trough that pushes loose material forward. Because of the incline, these conveyors are not able to transport liquid materials. Instead, they convey powders, solid food ingredients, loose mixtures and pastes.

The slope of an inclined screw conveyor determines the amount of material that it may hold at one time. As the angle increases and becomes steeper, the conveyor's capacity decreases. For example, a conveyor carrying material up a 15º angle is able to carry 75% of its horizontal capacity, while a conveyor operating at 25º holds only 50% of its horizontal capacity. Inclined conveyors should never have internal screw supports, as they obstruct the production flow.

Since the material tends to fall back because of gravity it must overcome, inclined screw conveyors use trough covers and tubular housings to keep the material from falling off or spilling. If necessary, inclined screw conveyors are able to stow away in a vertical position when they are not needed, which saves storage space. They are often attached to a vat, mixer, tank, silo or oven and are most often used when material is transported from a small container to a large one that is much higher up. Because of the constant rotation of the spiral screw, inclined screw conveyors may also perform some additional blending or homogenizing during transportation.

Bulk Bag Handling

Bulk Bag Handling Industrial Dryers

Industrial Dryers Mixers & Blenders

Mixers & Blenders Palletizers

Palletizers Pneumatic Conveyors

Pneumatic Conveyors Screw Conveyors

Screw Conveyors Vibratory Feeders

Vibratory Feeders Weighing Systems & Scales

Weighing Systems & Scales Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services