Plastic screw conveyors are light in weight, inexpensive to fabricate and repair, corrosion and chemical-resistant and able to withstand high temperatures. They can also handle abrasive wear. Plastics like polyurethane, polyethylene and polypropylene can be injection molded to become these conveying systems. Read More…

We are a US based, family owned company specializing in the design and manufacturing of screw conveyors in all configurations: vertical, inclined, shaftless, live bottom, plug screws, feeders, mixers, heating/cooling, FDA/USDA approved, screw presses and more.

Automated Flexible Conveyor (AFC) designs and manufactures the SPIRALFEEDER(TM) flexible screw conveyors to automatically transfer, load, weigh, and unload powders, pellets, granules, mixtures, and other dry, bulk materials fast, gently, and safely. Expert engineers offer decades of experience in designing the ideal custom screw conveyor for your bulk material handling application. Try your...

At Akona Process Solutions, we take pride in engineering screw conveyors that provide reliable and efficient material handling for a wide range of industries. We design our conveyors to move bulk materials with precision, ensuring smooth and consistent flow whether the application involves powders, granules, or heavier solids.

Conveyance Solutions by Continental is a leading manufacturer of bulk material-handling equipment. We design equipment to suit your needs through manufacturing, prompt delivery and installation and start-up. We serve the cement, coal, food, gypsum and other industries. We construct with carbon steel, various grades of stainless steel and other exotic metals. Call today for screw conveyors.

At American Bin and Conveyor, we specialize in designing and manufacturing screw conveyors that keep material handling efficient, reliable, and tailored to the needs of our customers. We take pride in engineering conveyors that move bulk materials with precision, whether handling powders, grains, aggregates, or other challenging materials.

More Plastic Screw Conveyor Manufacturers

Polyurethane screw conveyors are acid resistant, durable and at times more wear resistant than steel. Polypropylene and polyethylene exhibit a smooth surface, making them easy to clean and sterilize. They are therefore used as a food grade material that will not contaminate edible material and is used in the food and beverage processing industries. All three of these thermoplastic materials can also withstand high temperatures without melting, burning or chemically changing. Plastic screw conveyors can be easier to handle and replace than other kinds of conveyors, and they can convey loose, granular, powder and pellet materials. The food, chemical and mineral processing, wastewater treatment and construction industries all use screw conveyors made of plastic in plants and manufacturing facilities as components in large processing lines.

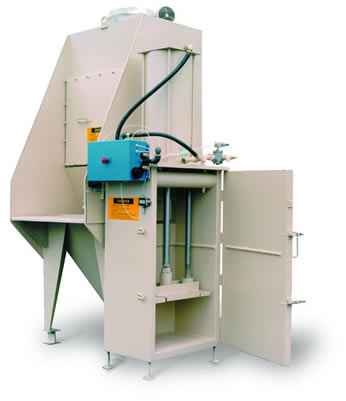

Like most screw conveyors, plastic screw conveyors are generally powered by an electric motor. They are available in six, nine or 12 inch diameters and may be any length, which is defined by the amount of space the facilities have. While plastic conveyors are used when impact and abrasive wear is a problem, they do have some limitations. Static electricity may accumulate and produce a spark while plastic screw conveyors are in motion. Therefore, absolutely no combustible or flammable materials may be transported via plastic screw conveyors in order to ensure workplace safety.

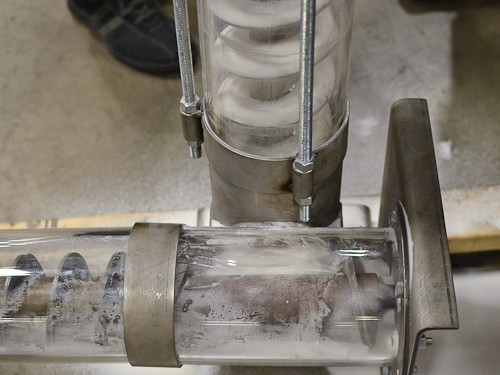

All plastic components of screw conveyors - the screw shaft and trough or tubular casing - are manufactured by the injection molding process, where molten thermoplastic resin is forced into a mold, where it takes the shape and hardens. Injection molding is fast, inexpensive and able to produce complex plastic parts. Screw conveyors made of plastic may be three different orientations: horizontal, which transports material on a level plane and often doesn't require a tubular casing; vertical, which conveys material straight up and down; and inclined, which moves material from one container to another on an angle. Most plastic screw conveyors, however, are modular or portable. They are smaller and can be relocated to anywhere they are needed around a facility.

Bulk Bag Handling

Bulk Bag Handling Industrial Dryers

Industrial Dryers Mixers & Blenders

Mixers & Blenders Palletizers

Palletizers Pneumatic Conveyors

Pneumatic Conveyors Screw Conveyors

Screw Conveyors Vibratory Feeders

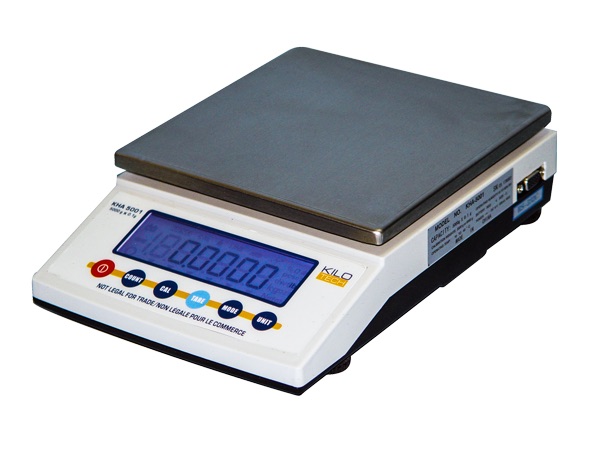

Vibratory Feeders Weighing Systems & Scales

Weighing Systems & Scales Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services