A perplexing problem that faces every material management manager is finding the most economical and efficient method for moving, storing, and supplying raw materials to production. Traditionally, the first thing that these supply chain experts think of is some form of belt conveying system, which is great for moving large parts and boxes but not small granular materials. Read More…

We are a US based, family owned company specializing in the design and manufacturing of screw conveyors in all configurations: vertical, inclined, shaftless, live bottom, plug screws, feeders, mixers, heating/cooling, FDA/USDA approved, screw presses and more.

Automated Flexible Conveyor (AFC) designs and manufactures the SPIRALFEEDER(TM) flexible screw conveyors to automatically transfer, load, weigh, and unload powders, pellets, granules, mixtures, and other dry, bulk materials fast, gently, and safely. Expert engineers offer decades of experience in designing the ideal custom screw conveyor for your bulk material handling application. Try your...

At Akona Process Solutions, we take pride in engineering screw conveyors that provide reliable and efficient material handling for a wide range of industries. We design our conveyors to move bulk materials with precision, ensuring smooth and consistent flow whether the application involves powders, granules, or heavier solids.

Conveyance Solutions by Continental is a leading manufacturer of bulk material-handling equipment. We design equipment to suit your needs through manufacturing, prompt delivery and installation and start-up. We serve the cement, coal, food, gypsum and other industries. We construct with carbon steel, various grades of stainless steel and other exotic metals. Call today for screw conveyors.

At American Bin and Conveyor, we specialize in designing and manufacturing screw conveyors that keep material handling efficient, reliable, and tailored to the needs of our customers. We take pride in engineering conveyors that move bulk materials with precision, whether handling powders, grains, aggregates, or other challenging materials.

More Screw Feeder Manufacturers

The feed screw mechanism, that has been around since ancient Egypt, is a screw conveyors that can efficiently and economically move powders, granular materials, wood chips, saw dust, and powdery materials from storage to production. Available in an assortment of feed screw designs and configurations of any size, these rapid feed screw mechanisms are the perfect solution for supplying production directly from storage.

What is a Screw Feeder?

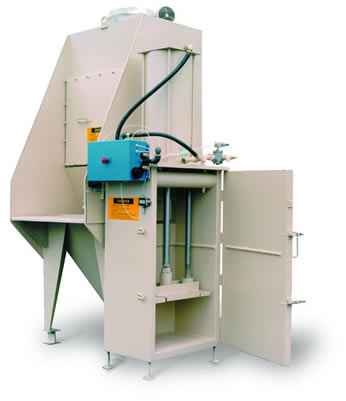

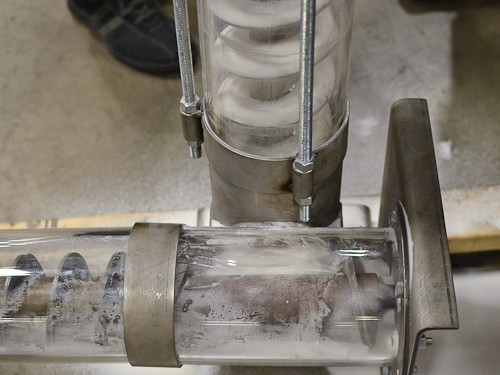

A screw feeder, in simplest terms, consists of a tube with a feed screw down the center. As raw materials are fed into the tube, the feed screw turns and moves the material along to a discharge unit located at the end of the tube. The type of screw and the angle of its blades controls the volume of material that is moved at each turn.

As simple as this description may be, it does not cover the necessary engineering expertise needed to design a proper feeding mechanism. There are a number of factors required to determine the use of this conveyance device. The first consideration is the pitch of the blades of the screw, which has to be perfect to fit the characteristics of the product.

Prior to determining the pitch. The distance between the blades has to be calculated since that will determine the amount of product for each flight, the flight being the area between the blades. Once the flight is decided, the pitch has to be calculated such that it isn’t too great to cause the feeder to jam or too small to not move a sufficient amount of product. These design factors are carefully calculated to ensure optimum performance.

Types of Screw Feeders –

As with any type of conveyance device, screw feeders have to be designed to exactly fit the requirements of the product to be moved. This factor is an essential part of the decision process and determines the type of screw feeder, feeding mechanism, and speed of conveyance.

Though the design of feeders seems rather simple, there are variations to fit every type of product. The most obvious difference is in the type of screw, which can be tapered, have variations in pitch, or be a combination of factors. The main consideration is the type of material since a different type of feeder is required for grain than is used for powders.

Benefits of Screw Feeders –

The first and most prominent factor regarding the benefits of a screw feeder is its durability. Unlike conventional feeding methods, a screw type feeder is made from durable materials that are not pliable but are engineered to last. From the hopper to the discharge, every element of a screw feeder is solid state metal that is designed for longevity and endurance.

Another benefit of a screw method of feeding is speed, which can be varied according to the need of production. In operations that require products to be mixed and finished in a set time, screw feeders are the best choice.

Bulk Bag Handling

Bulk Bag Handling Industrial Dryers

Industrial Dryers Mixers & Blenders

Mixers & Blenders Palletizers

Palletizers Pneumatic Conveyors

Pneumatic Conveyors Screw Conveyors

Screw Conveyors Vibratory Feeders

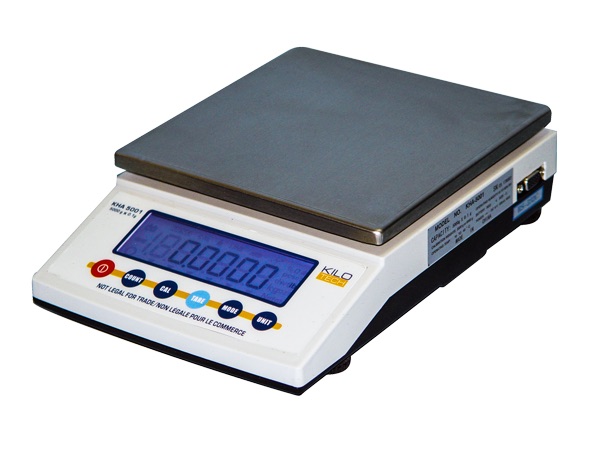

Vibratory Feeders Weighing Systems & Scales

Weighing Systems & Scales Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services